By Paolo Surico, Project Syndicate | Feb 3, 2026

Technological leadership is often framed as a matter of singular breakthroughs rather than institutional capacity. But the rapid development of penicillin during World War II shows that coordinated public leadership, strong research institutions, and a dynamic private sector produce results no other innovation system can achieve.

LONDON – When we think about wartime innovation, we usually imagine dramatic breakthroughs: Alan Turing’s cracking of the Nazi Enigma code, the invention of radar, the Manhattan Project’s development of the atomic bomb. But a less visible biological innovation – the mass production of penicillin – was just as transformative.

Although Alexander Fleming identified penicillin’s antibacterial properties in 1928, it remained fragile, unstable, and almost impossible to produce in meaningful quantities for more than a decade. It was only during World War II that penicillin was turned into a treatment that could be produced, distributed, and widely used.

The stakes could not have been higher. Estimates from military records indicate that during World War I, roughly 12-15% of soldiers wounded in battle died from bacterial infections. For some injuries – most notoriously femur fractures – mortality rates reached 80%, almost entirely due to post-wound complications. Survival often depended less on the severity of the injury than on sheer luck.

By the final years of World War II, once the Allies began mass-producing penicillin, medical outcomes changed dramatically. Military records show infection recovery rates of around 95%, far surpassing the efficacy of earlier antiseptics and sulfa drugs. Mortality from comparable wound infections fell to roughly 3-4%, and penicillin is estimated to have prevented tens of thousands of amputations that previously would have been necessary to stop the spread of gangrene. Equally important, it sharply reduced recovery times, shortening convalescence from months to just a few weeks.

Mass production of penicillin was as consequential to the Allied war effort as any breakthrough in cryptography or nuclear physics. Despite its formidable scientific capacity, Germany failed to do so. Research efforts began late, remained confined to a handful of university labs, and stalled at the experimental stage, as Nazi scientists lacked access to high-yield strains, advanced fermentation methods, and – most critically – the institutional coordination necessary for large-scale production.

The Allied experience was markedly different. From 1941 onward, the United States mobilized its scientific and industrial infrastructure through Vannevar Bush’s Office of Scientific Research and Development, funding parallel research projects across universities, public laboratories, and private firms while absorbing the financial and scientific risks. By adapting deep-tank fermentation techniques – originally developed for food processing and industrial chemistry – 21 American companies, including Pfizer, were able to produce millions of penicillin doses in time for D-Day.

Three features of the American innovation system proved decisive. First, penicillin manufacturing could be scaled only because of sustained investment in civilian technologies developed long before the war, such as fermentation, and in microbiology and industrial engineering. This non-military technological base became a strategic wartime asset. Germany, despite its strength in synthetic chemistry, lacked the diversified industrial ecosystem needed to manufacture antibiotics at scale.

Second, the US innovation environment was shaped by a government willing to take risks. At the start of the war, penicillin was experimental, expensive, and highly uncertain, giving private firms little incentive to invest. But President Franklin Roosevelt’s administration recognized that technological progress requires a tolerance for failure. Through the Office of Scientific Research and Development, it financed a wide range of exploratory efforts, fully expecting many to fail. In doing so, it allowed the most promising approaches to emerge and scale. Germany’s more centralized research system, by contrast, emphasized immediate military payoff and discouraged open-ended experimentation.

Third, the US built an innovation system that, though dispersed, was highly integrated, linking public investment, academic discovery, and industrial execution. The government set priorities and absorbed early risk; universities and laboratories advanced the science; and private firms translated discoveries into mass production. This division of labor gave the Allies a technological advantage that Nazi Germany, constrained by institutional rigidity, could not replicate.

In a recent paper, my co-authors and I argue that the penicillin story illustrates a broader pattern in the evolution of American technology. Since World War II, the most transformative US-led breakthroughs – from semiconductors to biotechnology – have relied on a distinctive institutional framework: publicly funded basic research, strong universities and research institutions, a competitive private sector capable of scaling new technologies, and large social returns from public investment in health and education.

Penicillin, initially justified as a defense investment, ultimately had as great an impact on the war as any weapon, and it transformed civilian medicine and global health. In this sense, America’s most powerful wartime asset was not a particular technology but the system that made such breakthroughs possible.

Accounts of the Allies’ victory often highlight a narrow set of technological achievements. In reality, the Allies prevailed not simply because they built better weapons, but because they created a deeper, more adaptable innovation ecosystem flexible enough to convert scientific knowledge into practical, life-saving tools when it mattered most.

That system did not emerge by accident. It was the product of deliberate policy decisions that aligned academic research, industrial capacity, and institutional development – a nexus that Donald Trump’s administration is jeopardizing by axing funding for basic research and targeted investment, especially for health (NIH) and science (NSF). Today’s policymakers need to recall the lesson of penicillin’s wartime development: true security depends as much on fostering innovation as on weaponry.

Paolo Surico is Professor of Economics at London Business School.

Copyright Project Syndicate

👉 Show & Tell 🔥 The Signals

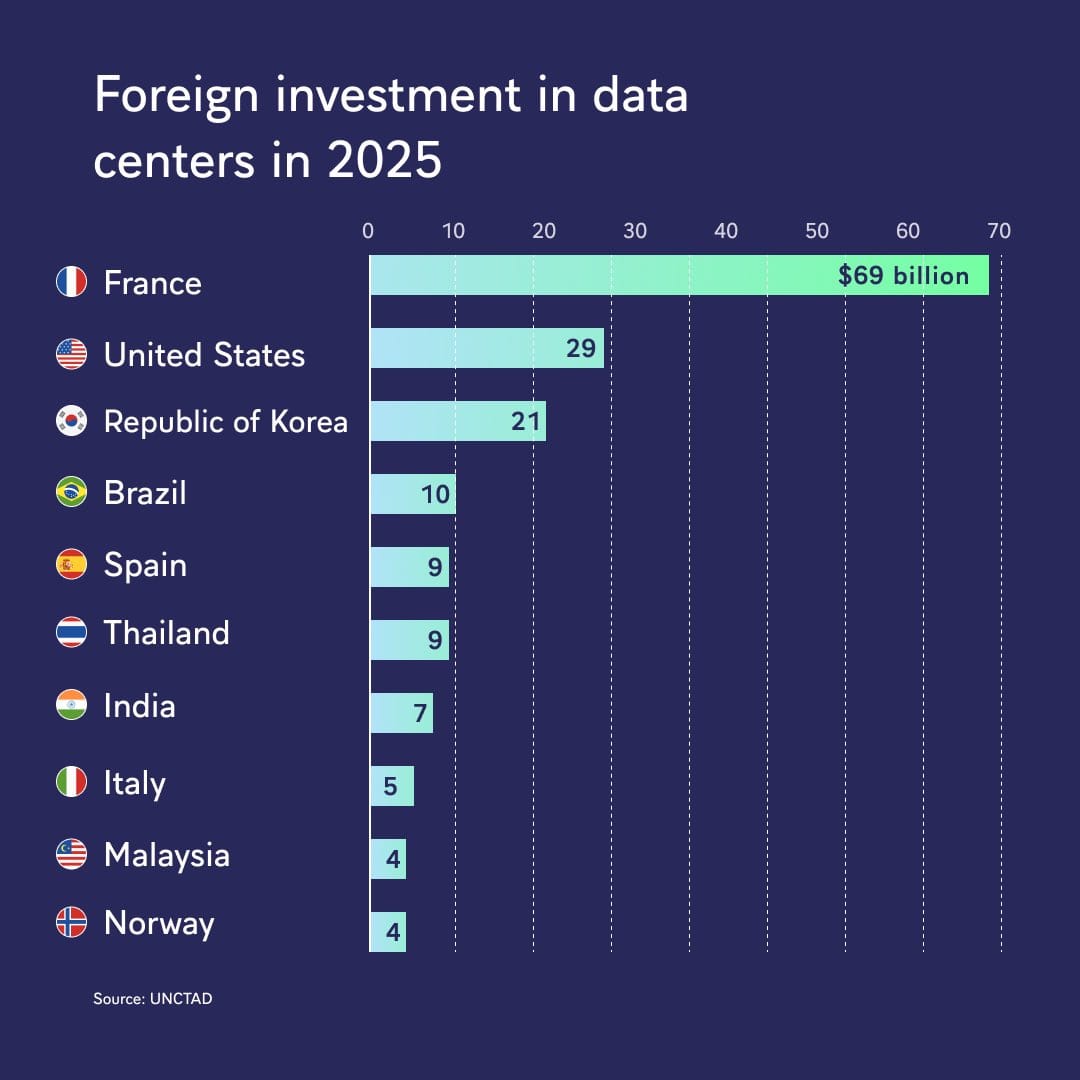

I. France Leads Global Data Center Investment In 2025

France is projected to attract about $69 billion in foreign investment in data centers in 2025, more than double the U.S. total, as countries compete to build infrastructure supporting AI and cloud computing growth.

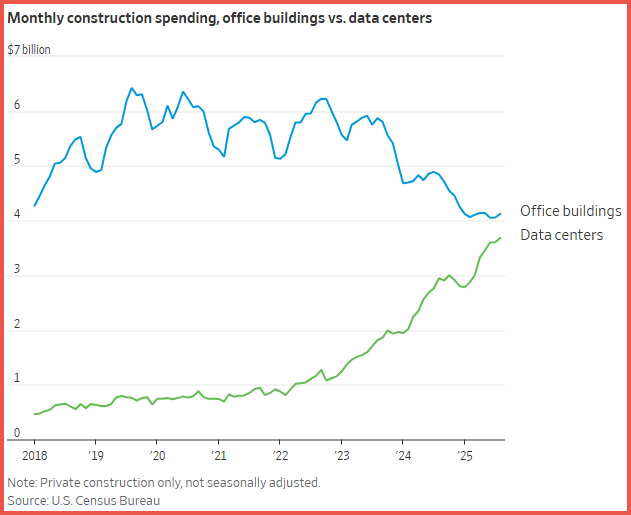

II. Data Center Construction Booms As Office Building Slows

Spending on U.S. data center construction has surged in recent years while office building construction has declined, reflecting weaker demand for office space and rising investment in digital infrastructure driven by cloud and AI growth.

III. Big Tech Ramps Up Spending On AI Infrastructure

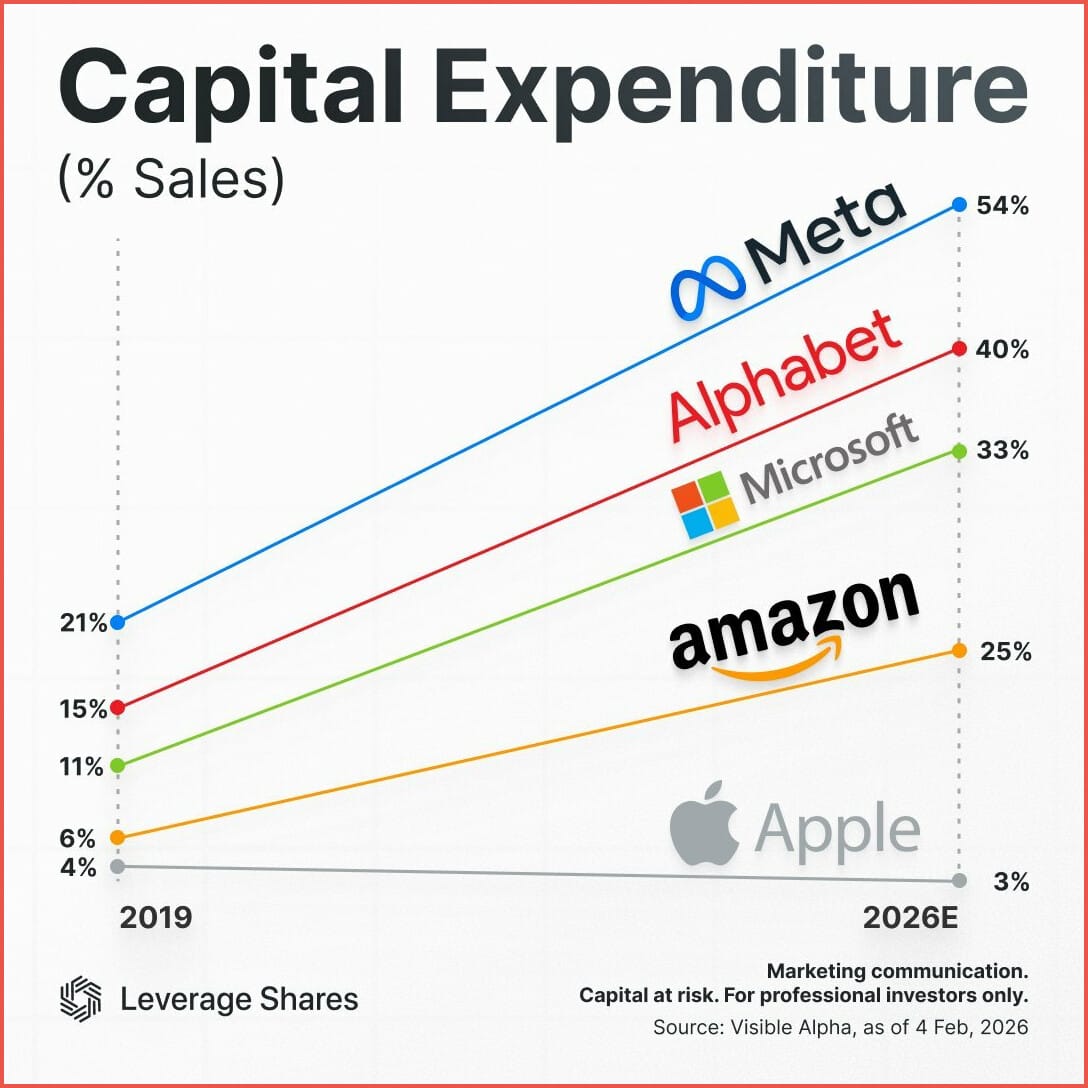

Major technology firms are sharply increasing capital spending to build AI and cloud infrastructure. Companies like Meta, Alphabet, Microsoft, and Amazon are now devoting a growing share of sales to capital investments as competition in AI accelerates.

📊 Market Mood — Monday, February 9, 2026

🟩 Futures Edge Higher to Start Busy Week

U.S. futures tick up as investors brace for heavy earnings and key economic data releases.

🟧 Chip Earnings Kick Off Crucial Tech Week

Onsemi reports today, with investors watching whether AI-driven chip demand offsets weakness in autos and other sectors.

🟦 Japan Stocks Rally After PM’s Election Win

Japanese markets rise after Prime Minister Sanae Takaichi secures a strong election mandate, easing political uncertainty.

🟨 Oil Slips as U.S.–Iran Talks Ease Tensions

Crude prices fall as continued nuclear negotiations reduce geopolitical risk premiums in energy markets.

🗓️ Key Economic Events — Monday, February 9, 2026

No events scheduled today

editor-tippinsights@technometrica.com